| Lost

Wax Injection Moulds |

We have an extensive experience in manufacturing moulds for Lost Wax

Injection. We have already developed a large variety of parts covering a

wide spectrum of industries like Automobiles, Aeronautical , Medical, Pumps,

Food Processing , Gas Turbines, Steam Turbines, etc. We provide total

solution for lost wax moulds & casting broadly categorized as follows:

Services

Precision Lost Wax Injection Mould Total Solution

- Complex Engineering Part's Mould for low volume production.

- Multi Cavity Precision Moulds For Big Volume Production.

- Moulds For Highly Intricate Parts.

|

- Moulds for Highly Contoured Parts.

- Moulds for Impellers, Propellers, and Twisted Blade Rotors of any

Configurations. This is one of our areas of Specialization.

|

Complex Engineering Part's Mould for Low

Volume Production.

Parts falling in these categories are mainly of low volume parts. They are

required in small numbers, or intended for functional prove out of processes

and fixtures, or prototype.

- For this kind of application we recommend single or two cavity

mould.

- Mould is designed to produce part which is complying to design

intent.

- The mould is maid out of Aluminum or Brass for easy

machinability.

|

- Loose Pieces and Inside cores are manual.

- Significantly low development cost compare to full fledge mould.

|

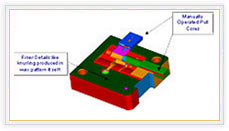

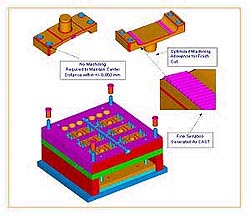

Multi Cavity Precision Moulds For Big

Volume Production.

Typical automobile parts fall in this category. These are the kinds of

parts which are required in large numbers in regular monthly production.

- Fully automatic mould typically produces 6 to 12 parts in one

cycle.

- The mould is provided with automatic ejector and core pulling

system.

- Manufactured out of alloy steel, for durability and protection to

damage.

- Increases the productivity of critical operation - molding of wax

patterns.

|

- Optimized machining stocks, reduction in machining time and

costs.

- Optimized shrinkage allowances, eliminates machining on wider

tolerance features.

- Higher Investment in mould - Results in very low per piece cost.

|

Moulds for Highly Intricate Parts.

Those types of parts falls in this category, where multi cavity mould is

just not feasible. These are the parts, which are designed to replace

subassemblies. Their applications include: Defense Applications, Optical

Systems, Aerospace Applications.

- In depth study of functional requirement of each feature of part.

- We suggest the design changes, which meet your design intent, and

falls with in process limitations of investment Castings and Mould

Manufacturing.

|

- Ability to design moulds for very intricate and complex shaped

parts.

- In house Manufacturing facility to keep close Watch on the

project as it progresses.

|

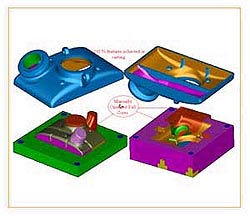

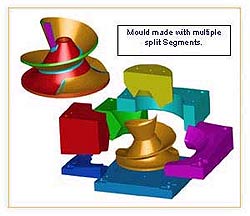

Moulds for Highly Contoured Parts.

We have developed our expertise in the manufacturing of moulds for the

parts having very specialized application, very complex surfaces and

irregular shapes. The final manufactured moulds negate the primary

assumption that moulds can not be developed for difficult parts.

- Technical Feasibility of mould itself is biggest highlights.

|

|

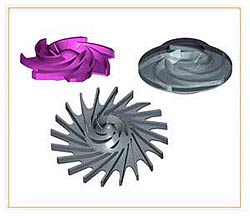

Moulds for Impellers, Propellers, and

Twisted Blade Rotors of any Configurations.

This is our area of specialization. Our R & D department has been

putting efforts to evolve efficient methods of designing and manufacturing

of twisted blade rotors.

- More than 100 bladed rotor moulds developed.

- Diameter size from 100mm to 500 mm

- Proprietary software's for designing of impeller moulds.

- Exact formation of leading edge radius.

|

- Ability to design and machine varying Blade thickness.

- A Typical delivery time 6 days, from your drawing to wax pattern

from mould.

- Solution for all latest Investment Casting Technologies in the

world. i.e. Ceramic, Lost wax, Masters for Soft Metal Mould, Soluble

Core System.

|

Total Solution :

- Twisted Blade Open Impeller Mould.

- Twisted Blade Twin Array Open Impeller Mould.

- Twisted Blade Close Impeller Mould.

|

- Twisted Blade Close Impeller Soluble Core Segment Mould.Twisted

Blade Close And Open Impeller Core Segment Machining for Soft Die

Technology Users.

- Twisted Blade Impeller Mould for Ceramic Mould Technology Users

|